GD-Glow in Dark

GD-Glow in Dark

Make Your Designs Shimmer and Sparkle!

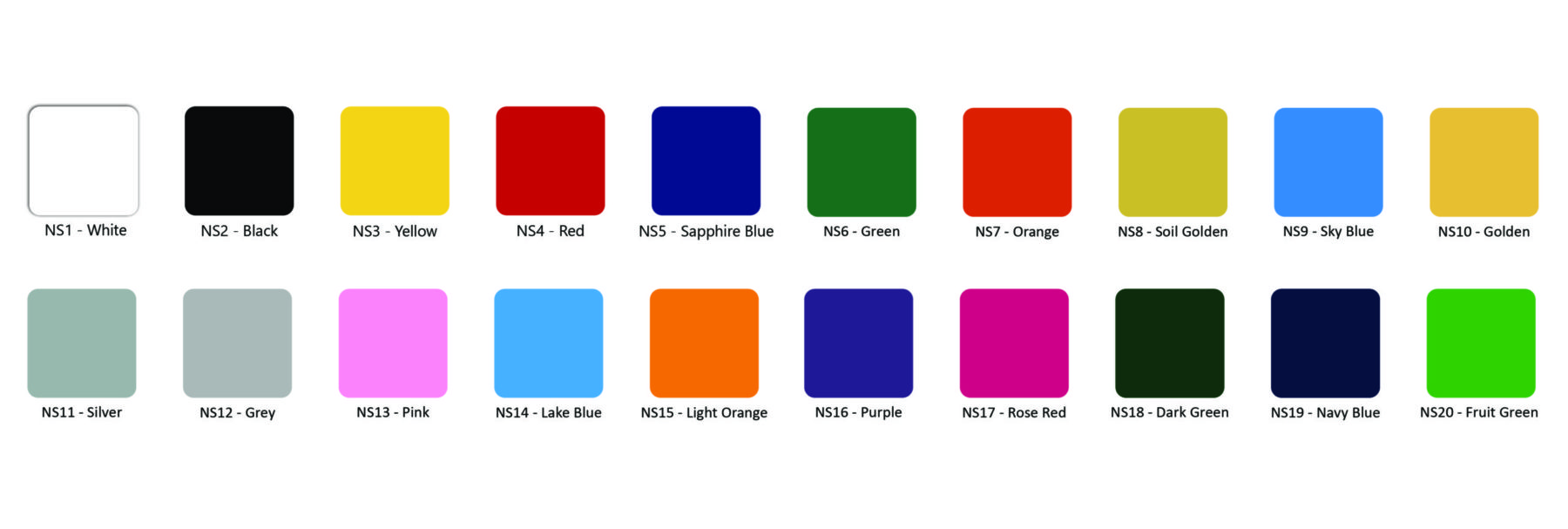

Glow in Dark. Sparkle™ Heat Transfer Vinyl is a fashionable alternative to Glitter HTV by Siser®. Specially constructed to be soft to the touch, each color includes silver glitter specks embedded in the material so designs have a smooth finish. Sparkle is available in 14 colors, including silver and gold. Looking to layer? Sparkle can be layered for ultimate bling! Think outside the box and use Sparkle HTV on shoes, belts, and other hard-to-print items. If you like to keep it simple, Sparkle can be applied to t-shirts, hoodies, sweats and scrubs too!

What is GD-Glow in Dark Technology?

GD-Glow in Dark technology is a photoluminescent material that emits light in the dark. It is often used as a coating for surfaces such as paint, plastics, or ceramics. The material is non-toxic, non-radioactive, and does not require an external power source to emit light.

How does GD-Glow in Dark Work?

GD-Glow in Dark works by absorbing ambient light during the day and releasing it at night. When the material absorbs photons, it excites electrons to higher energy levels. When the electrons return to their original energy state, they release photons in the form of light. This process is known as photoluminescence.

The History of GD-Glow in Dark

GD-Glow in Dark technology has been around for over a century, with the first patents for photoluminescent materials dating back to the early 1900s. However, it wasn’t until the 1990s that the technology became widely used in safety and emergency signage. Since then, GD-Glow in has continued to evolve, with advancements in materials and application methods leading to increased versatility and durability.

Applications of GD-Glow in Dark

Safety and Emergency Signage

One of the most common applications of GD-Glow in Dark is for safety and emergency signage. This includes exit signs, fire safety signs, and warning signs. GD is often used in these applications because it is reliable, long-lasting, and requires no external power source.

Automotive and Aviation Industries

GD is also used in the automotive and aviation industries. It can be applied to instrument panels, controls, and safety markers. In these applications, GD-Glow in provides visibility in low-light conditions, improving safety and efficiency.

Consumer Products

GD-Glow in Dark can also be found in a variety of consumer products such as watches, clocks, and toys. These products often use GD- to enhance their aesthetics and provide visibility in the dark.

Healthcare Industry

In the healthcare industry, GD-in Dark is used in medical equipment, and emergency lighting. In addition, evacuation maps. It helps to ensure the safety of patients and medical personnel in low-light conditions.

Military and Defense

The military and defense industries also use GD- technology. In addition, It is used for everything from night vision equipment to marking targets in low-light environments.

Sparkle applies To

100% Cottoned

100% Polyester

Poly/Cotton Blends

Leather

Sparkle™ Snowstorm

Settings for Craft and Professional Cutters

How to apply VENYL® HTV

Printable version of all HTV application instructions

Home Iron Instructions

- Home Iron Instructions

- Set iron dial between Cotton and Linen

- Cover with Heat Transfer Cover Sheet or Multipurpose Paper

- Place on flat, hard surface (ironing board not recommended)

- Press iron with medium/firm pressure (do not slide iron)

Heat Press Instructions

- Cover with Heat Transfer Cover Sheet or Multipurpose Paper

- Preheat garment for 2-3 seconds

- Apply design at 305°F/150°C (EasyPress® users add approx. 30°)

- Use medium pressure for 10-15 seconds

- Peel carrier hot or cold

Recommended Accessories:

Multipurpose Paper or Heat Transfer Cover Sheet Wait 24 hours before first wash. Machine wash warm or cold with mild detergent. Dry on normal dryer setting. Do not dry clean.

Liquid fabric softener not recommended.