DTF – Direct To Film

DTF – Direct To Film

DTF is a translucent PET (polyethylene terephthalate) film having a thickness of 75-80 microns, designed to be used in DTF (Direct to Film) printing.

It is a new innovative transfer technology that garment decorators, with treated surfaces on both sides for optimal printing. Enjoy easy transfer without precise trimming or peeling.

Enhanced durability with unique inks and adhesive powder. Vibrant colors, excellent washing durability, and stretchable properties for superior performance.

Ideal for workwear, sportswear, fashion, polyester, canvas, leather, denim and promotional garments etc

How do you apply the Adhesive Powder and Cure the printed transfers?

Get started by applying the process manually with a drawer oven or a heat press with a dwell function.

To boost production and cut labor costs, consider using an automatic shaker unit. This machine does it all in one go – applying powder and curing.

The ink goes on the film, the powder sticks to the ink, and you can collect and reuse any leftover powder.

DTF Applies to

100% Cottoned

100% Polyester

Poly/Cotton Blends

Leather

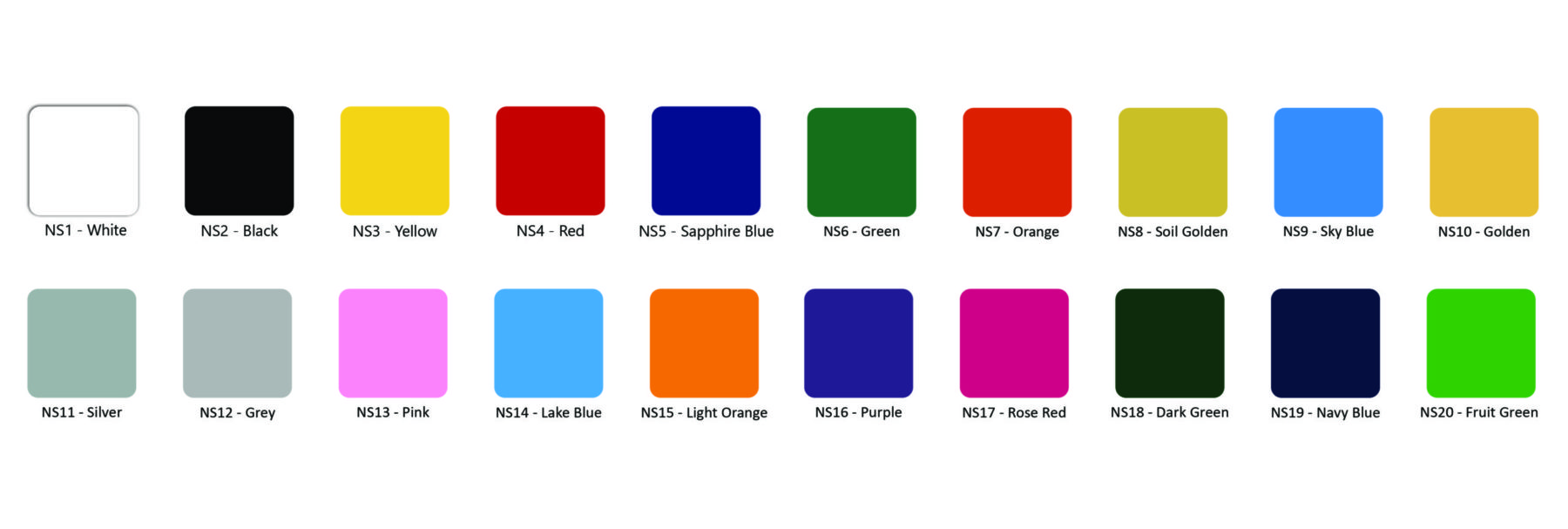

COLOR BOOK

RECOMMENDED MODELS FOR EPULS CUTTER - LAUNCHING SOON

How to apply VENYL® HTV

Printable version of all DTF application instructions

Home Iron Instructions

- Line up your artwork in the desired print area.

- Place the parchment paper or Teflon Sheet over the transfer for 20 seconds, pressing down with hard pressure.

- Set your iron on towards cotton/linen (Temperature 150-160C) with hard pressure

- Let your design transfer

- Place the parchment paper or Teflon paper over the design and press again for 15 seconds to soften the design, increase durability, and remove shine.

- Once cool, lift the transfer from one corner and gently peel back.

Heat Press Instructions

- Line up your artwork in the desired print area.

- Pre-press your garment for 10 seconds to remove any moisture wrinkles of the garment.

- Set your heat press machine to 140-160 C degrees.

- Proceed to heat-press the decal to the shirt with 10-15 seconds, cover with Teflon sheet.

- Let the T-shirt cool before removing the transfer film.

- Once cool, lift the transfer from one corner and gently peel back.

- Second press and cover with Teflon Sheet or Parchment paper for 10 seconds for adherence.

Important note after the application of DTF

- Wait 24 hours before the first wash.

- Machine wash warm or cold with mild detergent.

- Dry on normal dryer setting. Do not dry clean.

- A liquid fabric softener is not recommended.